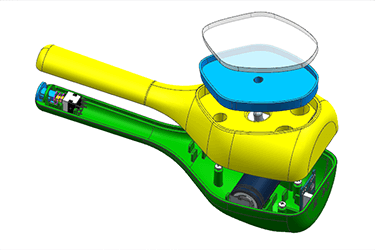

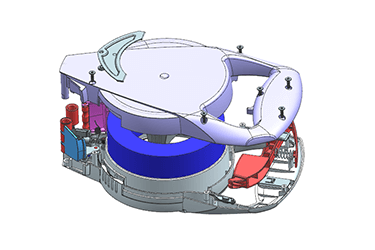

Do you have a design concept that you're very satisfied with or perhaps already have a conceptual design? In the process of product development, these conceptual designs are often closely tied to the manufacturability of the parts. With over 100 projects developed in the past, we are very familiar with the manufacturing processes of products. Whether it's plastic, sheet metal, die-casting, standard part selection, or custom components, we can provide you with a satisfactory manufacturability solution. Our robust industrial design team can tailor differentiated solutions for your product based on the consumer demographic, helping you seize a market advantage in product selection. Whether you desire a metal-textured plastic product or plastic-textured metal components, don't hesitate to contact us.

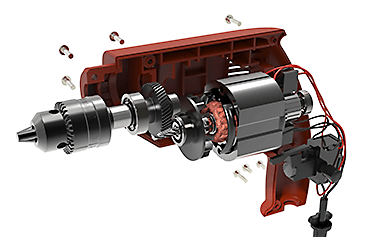

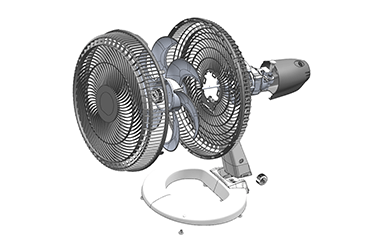

Structural design is often more challenging; besides manufacturability, one must also consider the cost, reliability, and, for certain industries, supply chain issues such as critical components and chips. A good structural design should also consider a reasonable assembly scheme. In the field of product development, we are pioneering the introduction of the 'Kaizen' philosophy. Even before a product enters the mass production stage, we've optimized it for you. As the saying goes, time is money. What could be more attractive than shortening the overall product development time? From the perspective of product cost, standard components can significantly reduce the product's cost, contingent on two factors:

1) a mature and complete supply chain system and 2) developers' understanding of the market.

While having a creative and marketable product is undoubtedly good, the competitive pricing of the product is equally important.