The purpose of rapid prototyping is to simulate the product's usage scenarios, bringing the risk assessment of product development forward to the prototype stage. With the advancement of technology, some processes can actually be directly used for mass production. Have you ever felt overwhelmed when trying to arrange the production of prototypes, considering various materials and manufacturing processes? Uni Engineering can help you solve this problem. Please organize your thoughts and divide the issue into two parts: what purpose do you need the prototype for, 'works like' and/or 'looks like'? Also, what kind of materials do you expect the product to use during mass production? Let us know your initial requirements, and we will provide you with the most suitable solution.

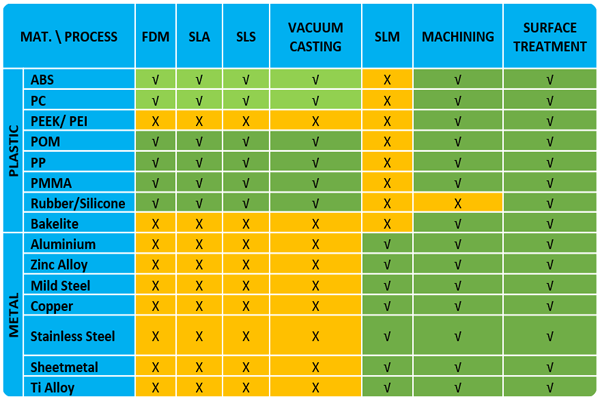

From the table on the right, you can see some commonly used materials and the processes available for them. Of course, the matching of these materials and processes is not fixed and can be adjusted. This is just a common set of processes based on economic principles.

If you have already determined the material and only need some blank samples for evaluation, I suggest sending the drawings to a local 3D printing service. If you have further requirements, you can contact Uni Engineering. Here are some examples:

1. 'Looks like' sample, which can be a complete set or partial components with surface treatment requirements or components that need to be assembled.

2. 'Works like' sample, typically requiring specific physical properties of the material. Additionally, 3D printing processes may not always meet the requirements, so it's necessary to choose suitable materials and processes based on individual cases.

3. Small batch production, which can be achieved through various processes. However, there are significant differences in time, material, and process costs. It's essential to choose a relatively economical solution while meeting the requirements.

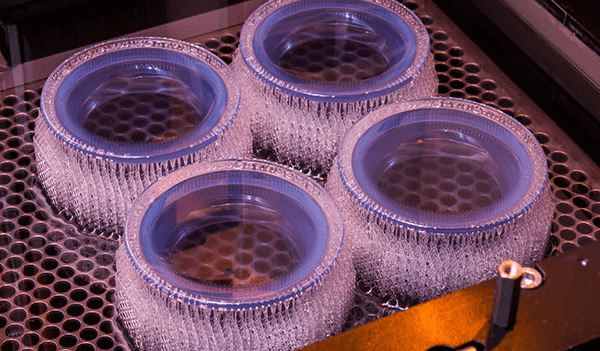

3D - Printed Prototype

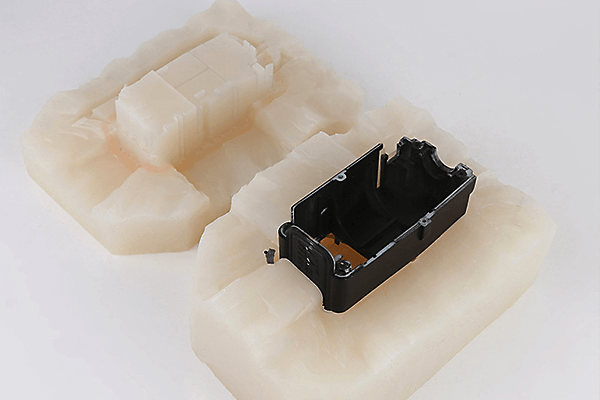

The vacuum casting process typically falls between 3D printing and molding. The geometric models of the prototypes produced by this process closely resemble those of molded parts. The material can be chosen based on the physical properties required for future mass production. With additional post-processing techniques, the samples closely approximate the quality produced by mass production molds. In some cases, these prototypes can even be directly applied in the final product. Generally, a set of vacuum casting silicone molds can produce 5-12 finished pieces, depending on the complexity of the product.