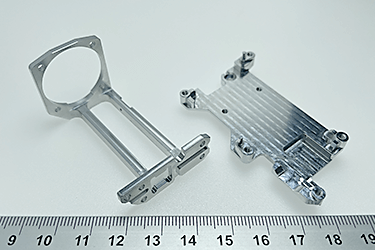

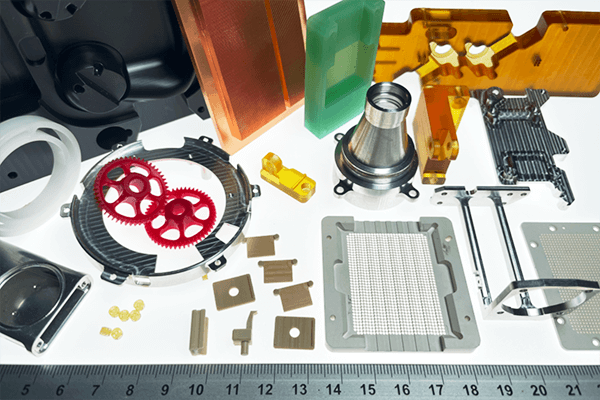

Many people pursue expensive machining equipment, and to some extent, this is justified. However, from my observations, many individuals actually waste these resources. When machine precision reaches a certain level, the determining factor for machining quality often lies not solely in the machine itself. For instance, the compatibility of tools and machining materials, the timing of coolant usage, the sequence of machining processes, the design of programmed toolpaths, the use of fixtures and gauges, a well-established quality control system, and even the packaging used for transit or transportation—all these factors, in most cases, play an equally important role in the quality of products produced through CNC machining. When Uni Engineering's engineering team receives your drawings, our team of experienced engineers will promptly provide you with professional assessment and formulate a rational machining process plan. What are you still considering? Contact us immediately.

Precision doesn't solely depend on the machine tool.