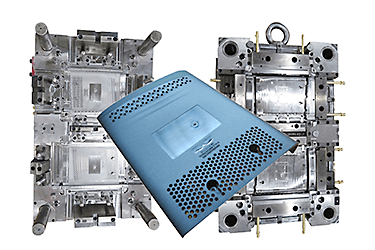

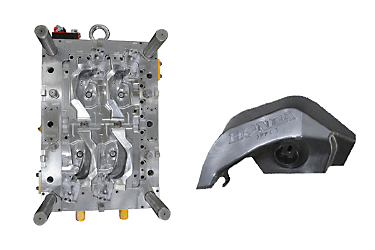

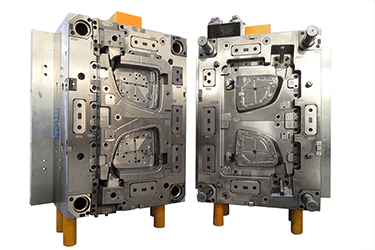

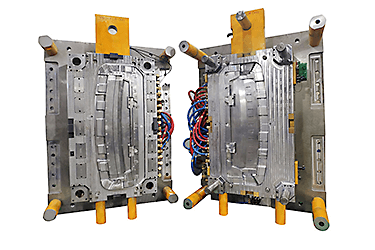

The definition of molds, for many designers, is like a black box - transforming the designed product into a physical form. However, Uni Engineering has a deeper understanding of molds. It's similar to purchasing a car, where the primary function is transportation, but buyer requirements can vary widely. Here, we can provide high, medium, and low-end mold solutions to ensure you can choose the most suitable option.

Before embarking on mold quoting, it's worth briefly reviewing two questions:

1. The purpose of the mold - Not all molds are intended for final production. Some projects, due to the need for extensive engineering validation before mass production, may require the creation of prototype molds. There are also projects where market demand is uncertain, and only small-batch production is needed in the short term, making prototype molds suitable. Generally, medium to low-end mold solutions can meet these needs. For molds used in mass production, strict requirements for lifespan, stability, production loss, and production cycle necessitate the use of high-end mold manufacturing solutions. Mass production molds are like efficient and stable cash printers, meeting the fundamental requirements of mass production molds.

2. Mold production plans - Where will the molds be produced? This introduces the concept of local molds and export molds. If you are a producer, you are likely to choose an export mold. We will design your mold according to the specifications of your production machinery and the mold standards used locally to ensure worry-free production and maintenance. If you only need components or assemble products locally, then a local mold is your optimal choice. Local production has price advantages, especially for complex molds with surface treatment requirements. In contrast, you only need to incur some additional transportation costs.